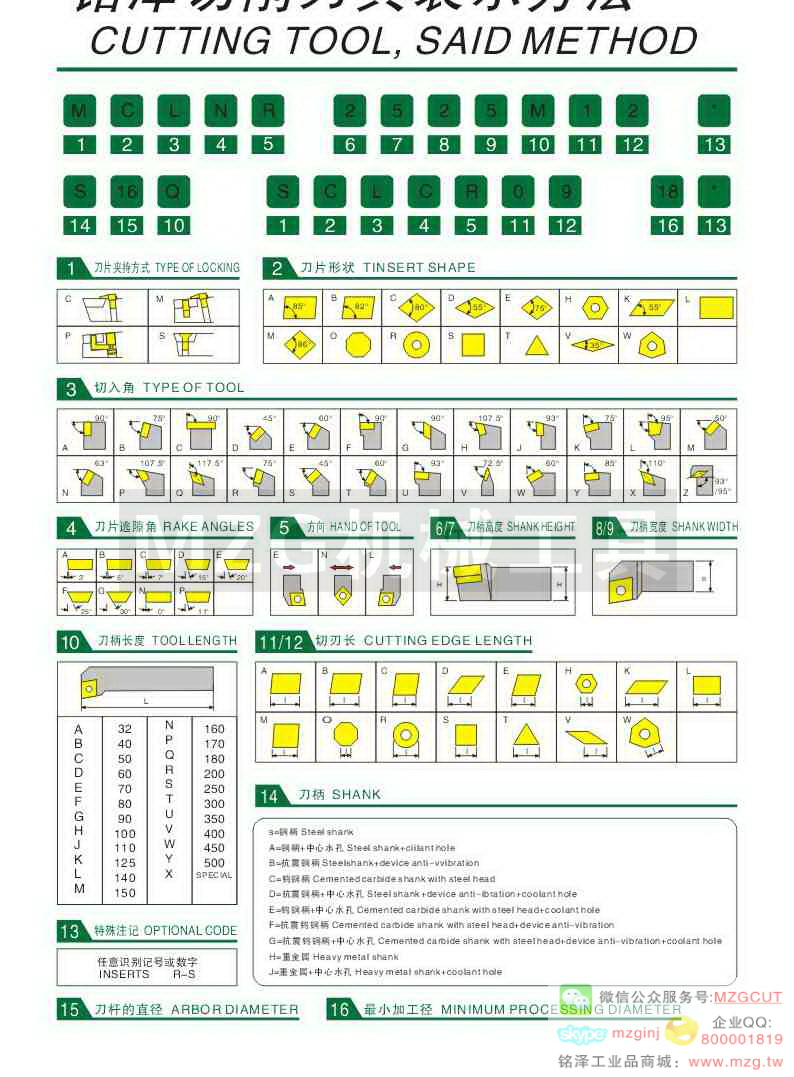

铭泽切削刀具表示方法 CUTTING TOOL, SAID METHOD 32 40 50 60 70 80 90 100 110 125 140 150 A B C D E F G H J K L M L 刀柄长度 TOOL LENGTH 10 切刃长 CUTTING EDGE LENGTH I I I I I I I I I I I I I I I 11/12 A B C D E H K L M O R S T V W 特殊注记 OPTIONAL CODE 13 任意识别记号或数字 INSERTS R-S 刀柄 SHANK 14 s=钢柄 Steel shank A=钢柄+中心水孔 Steel shank+ciilant hole B=抗震钢柄 Steelshank+device anti-vvibration C=钨钢柄 Cemented carbide shank with steel head D=抗震钢柄+中心水孔 Steel shank+device anti-ibration+coolant hole E=钨钢柄+中心水孔 Cemented carbide shank with steel head+coolant hole F=抗震钨钢柄 Cemented carbide shank with steel head+device anti-vibration G=抗震钨钢柄+中心水孔 Cemented carbide shank with steel head+device anti-vibration+coolant hole H=重金属 Heavy metal shank J=重金属+中心水孔 Heavy metal shank+coolant hole 160 170 180 200 250 300 350 400 450 500 SPECIAL N P Q R S T U V W Y X A B C D E F G N P 90° 75° 90° 45° 60° 90° 90° 107.5° 93° 75° 95° 50° 63° 107.5° 117.5° 75° 45° 60° 93° 72.5° 60° 85° 3° 5° 7° 15° 20° 25° 30° 0° 11° 切入角 TYPE OF TOOL 刀片逃隙角 RAKE ANGLES 3 A B C D E F G H J K L M N P Q R S T U V W Y X 4 H H 刀柄高度 SHANK HEIGHT 6/7 方向 HAND OF TOOL E N L 5 B 刀柄宽度 SHANK WIDTH 8/9 85° 82° 80° 55° 75° 55° 86° 35° 刀片夹持方式 TYPE OF LOCKING 刀片形状 TINSERT SHAPE 1 2 C M P S A B C D E H K L M O R S T V W M C L N R * 1 2 3 4 5 2 5 2 5 M 1 2 6 7 8 9 10 11 12 13 S 16 Q 14 15 10 S C L C R 0 9 1 2 3 4 5 11 12 18 * 16 13 15 16 刀杆的直径 ARBOR DIAMETER 最小加工径 MINIMUM PROCESSING DIAMETER 110° 93° /95° Z

铭泽切削刀具表示方法 CUTTING TOOL, SAID METHOD 32 40 50 60 70 80 90 100 110 125 140 150 A B C D E F G H J K L M L 刀柄长度 TOOL LENGTH 10 切刃长 CUTTING EDGE LENGTH I I I I I I I I I I I I I I I 11/12 A B C D E H K L M O R S T V W 特殊注记 OPTIONAL CODE 13 任意识别记号或数字 INSERTS R-S 刀柄 SHANK 14 s=钢柄 Steel shank A=钢柄+中心水孔 Steel shank+ciilant hole B=抗震钢柄 Steelshank+device anti-vvibration C=钨钢柄 Cemented carbide shank with steel head D=抗震钢柄+中心水孔 Steel shank+device anti-ibration+coolant hole E=钨钢柄+中心水孔 Cemented carbide shank with steel head+coolant hole F=抗震钨钢柄 Cemented carbide shank with steel head+device anti-vibration G=抗震钨钢柄+中心水孔 Cemented carbide shank with steel head+device anti-vibration+coolant hole H=重金属 Heavy metal shank J=重金属+中心水孔 Heavy metal shank+coolant hole 160 170 180 200 250 300 350 400 450 500 SPECIAL N P Q R S T U V W Y X A B C D E F G N P 90° 75° 90° 45° 60° 90° 90° 107.5° 93° 75° 95° 50° 63° 107.5° 117.5° 75° 45° 60° 93° 72.5° 60° 85° 3° 5° 7° 15° 20° 25° 30° 0° 11° 切入角 TYPE OF TOOL 刀片逃隙角 RAKE ANGLES 3 A B C D E F G H J K L M N P Q R S T U V W Y X 4 H H 刀柄高度 SHANK HEIGHT 6/7 方向 HAND OF TOOL E N L 5 B 刀柄宽度 SHANK WIDTH 8/9 85° 82° 80° 55° 75° 55° 86° 35° 刀片夹持方式 TYPE OF LOCKING 刀片形状 TINSERT SHAPE 1 2 C M P S A B C D E H K L M O R S T V W M C L N R * 1 2 3 4 5 2 5 2 5 M 1 2 6 7 8 9 10 11 12 13 S 16 Q 14 15 10 S C L C R 0 9 1 2 3 4 5 11 12 18 * 16 13 15 16 刀杆的直径 ARBOR DIAMETER 最小加工径 MINIMUM PROCESSING DIAMETER 110° 93° /95° Z