MZG 10mm 12mm SNR0010K11 S Type CNC Lathe Machining Cutter Internal Threaded Tools Threading Toolholders Thread Turning Holder

1.MZG Turning Tools Item Specifics

MZG Turning Tools Specification Parameter

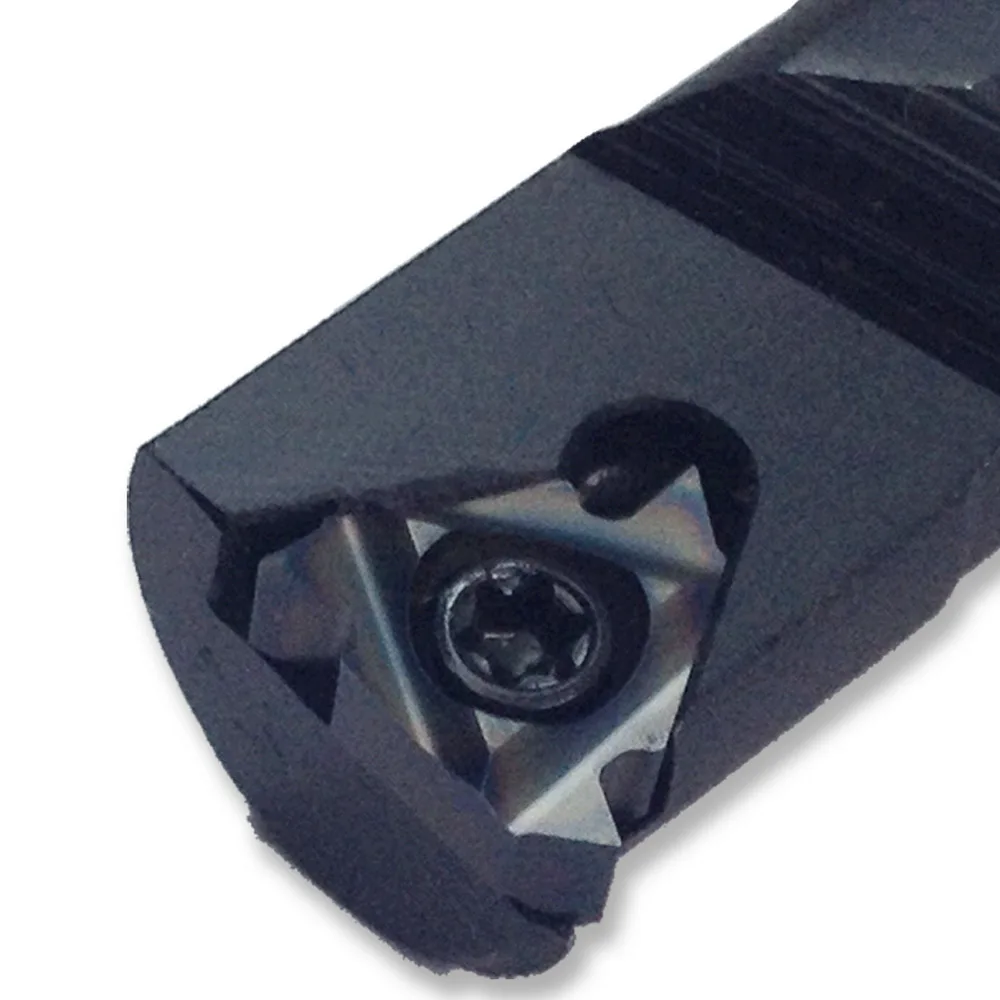

2.MZG Turning Tool Product Photo

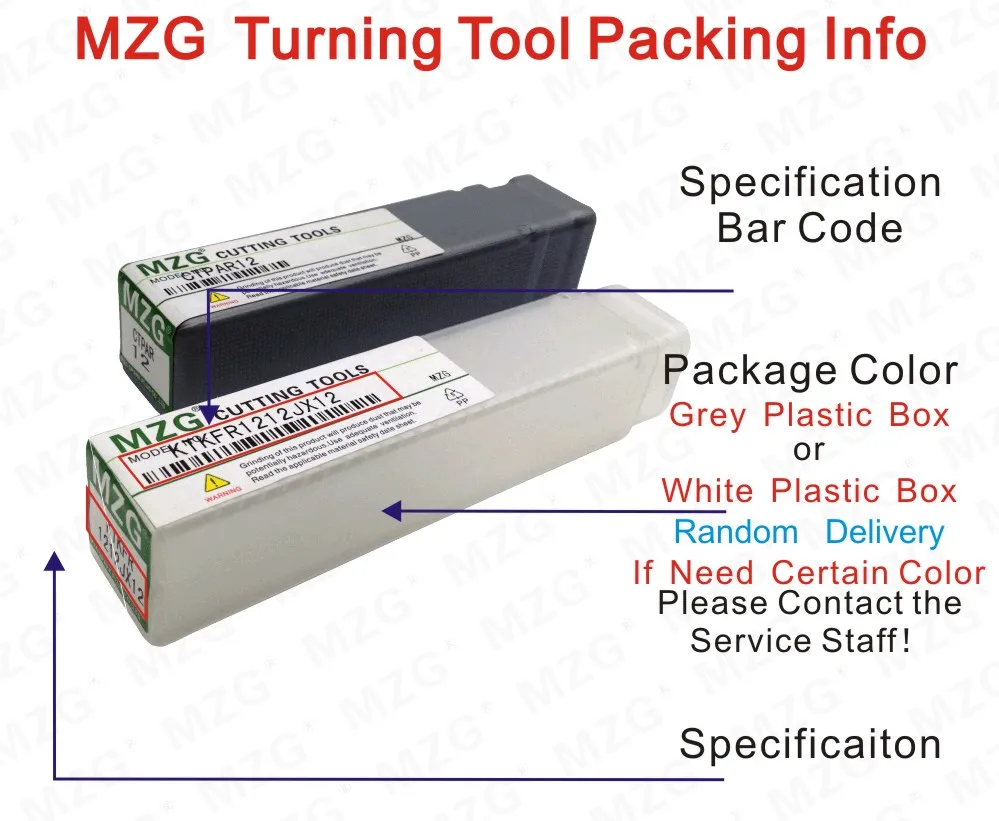

3.MZG Turning Tool Packing Info

3.MZG Turning Tool Packing Info

Turning Tool Packing Info

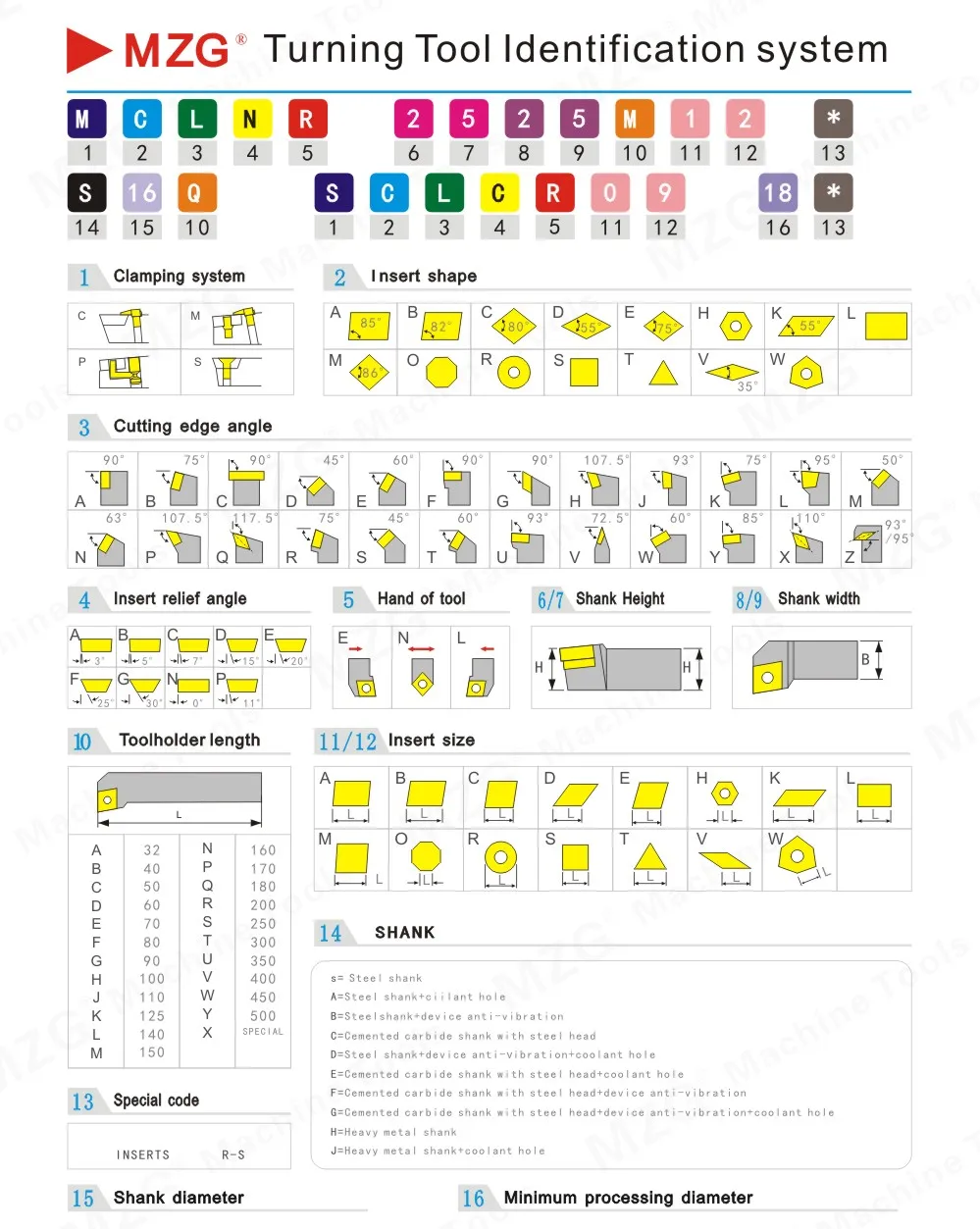

4.MZG Turning Tool Parameter

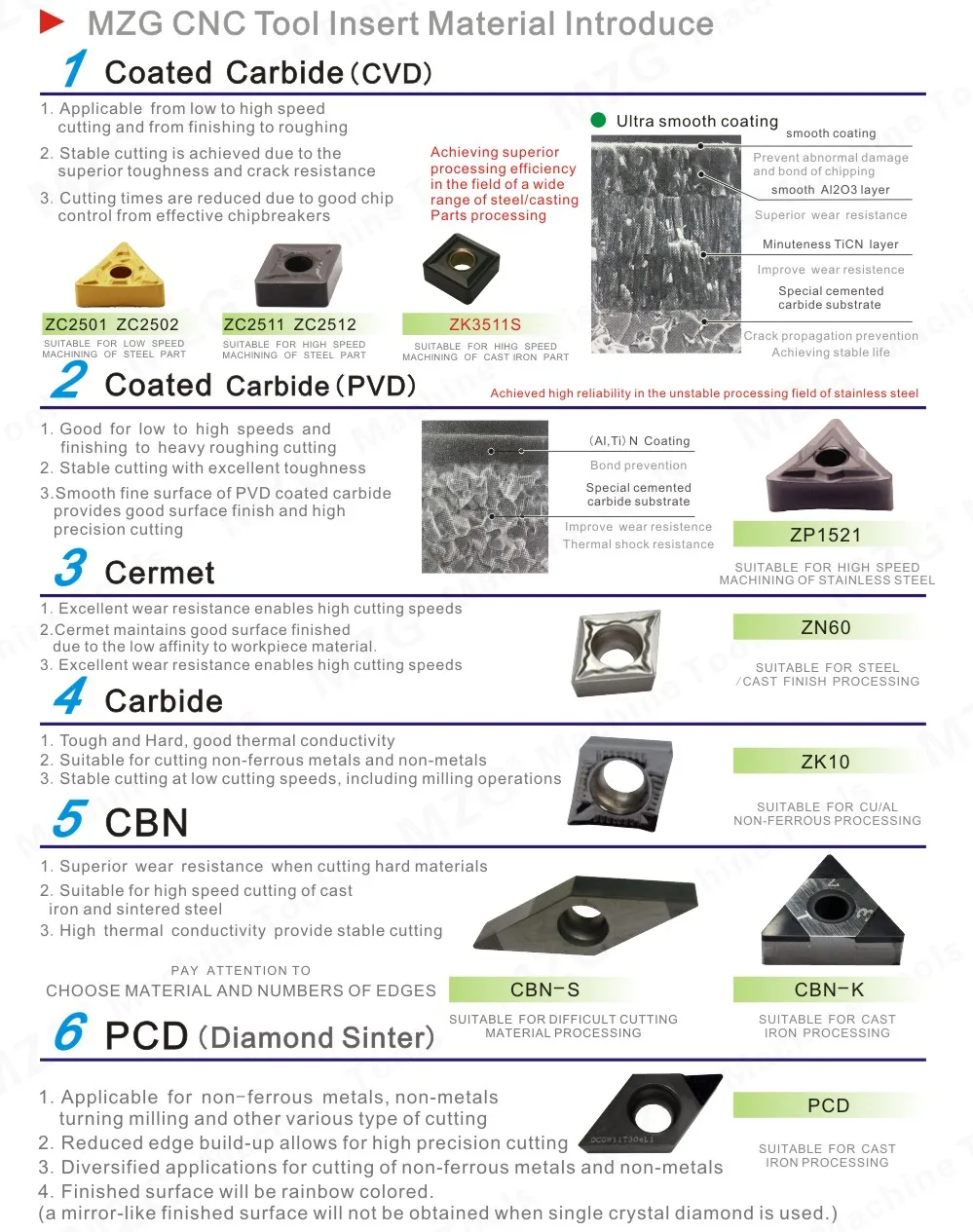

MZG CNC Tool Insert Material Introduce

1.Coated Carbide(CVD)

Applicable from low to high speed cutting and from finishing to roughin.

Stable cutting is achieved due to the superior toughness and crack resistance.

Cutting times are reduced due to good chip control from effective chipbreakers.

Achieving superior processing efficiency in the field of a wide range of steel/casting Parts processing.

ZC2501 ZC2502 : suitable for low speed machining of steel part

ZC2511 ZC2512 : suitable for high speed machining of steel part

ZK3511S : suitable for hihg speed machining of cast iron part

2.Coated Carbide(PVD)

Good for low to high speeds and finishing to heavy roughing cutting.

Stable cutting with excellent toughness.

Smooth fine surface of PVD coated carbide provides good surface finish and high.

Achieved high reliability in the unstable processing field of stainless steel

ZP1521 : suitable for high speed machining of stainless steel

3.Cermet

Excellent wear resistance enables high cutting speeds

Cermet maintains good surface finished due to the low affinity to workpiece material.

Excellent wear resistance enables high cutting speeds.

ZN60 : suitable for steel/cast finish processing

4.Carbide

Tough and Hard, good thermal conductivity

Suitable for cutting non-ferrous metals and non-metals

Stable cutting at low cutting speeds, including milling operations

ZK10 : suitable for Cutting Aluminum Al non-ferrous processing

5.CBN

Superior wear resistance when cutting hard materials

Suitable for high speed cutting of cast iron and sintered steel

High thermal conductivity provide stable cutting

CBN-S : suitable for difficult cutting material processing

CBN-K : suitable for cast iron processing

6.PCD (Diamond Sinter)

Applicable for non-ferrous metals, non-metals turning milling and other various type of cutting .

Reduced edge build-up allows for high precision cutting.

Diversified applications for cutting of non-ferrous metals and non-metals.

Finished surface will be rainbow colored.(a mirror-like finished surface will not be obtained when single crystal diamond is used.)

PCD : suitable for cast iron processing

5.MZG Tungsten Carbide Inserts Instruction

Safety Notes for Cutting Tool

1 Introduction

MZG has put a "caution" or a "warning" label on the package of the cutting tool products, but it is not on the tool itself.

Before using and handling any cutting tool products and cutting tool materials, be sure to read this guideline so they are used correctly.

Also, as part of your safety education,please make sure to familiarize all of your actual operators with the contents of this guideline.

2 Basis Information for Cutting Tool Materials

2-1 Technical Terms

Cutting Tool Material: Terminology for cutting tool materials,such as Cemented Carbide, Coated Carbide,Cermet, Coated Cermet,Ceramics, CBN and PCD.

Carbide Material: Cement Carbide with WC(Tungsten Carbide) as the main component.

2-2 Physical Properties

Apprearance: Depends on materials(e.g. Grey,Black,Gold,ect.)

Smell:None

Hardness:Carbide/Cermet 5~30GPaHV, Ceramic 10-40 GPaHV

CBN 20~50GPaHV,PCD 80~120 GPaHV

Sp.Gr.:Carbide 9~16, Cermet 5~9, Ceramic 2~7,CBN/PCD 3~5

2-3 Composition

Carbide, Nitride,Carbon-nitride and Oxide with W,Ti, Al, Si, Ta,B, ect. and additionally,metal such as Co, Ni, Cr,Mo are included in some cutting material.

Precaution for using cutting tool

1.General Cutting Tools

Precaution for using cutting tools

Precariousness: Direct touch to a sharp cutting edge may cause injury.

Countermeasures: When you set up tools to the machine or take tools out of the case, please wear protective gloves.

Precariousness: Misuse or inappropriate working conditions may cause tool breakage or dispersion of broken pieces.

Countermeasures:Please use safety item, such as safety glasses and protective gloves

Please use in the range of our recommended cutting condition. See our catalog or instruction manuals.

Precariousness: Excessive impact or heavy wear will increase cutting resistance and may cause tool breakage and dispersion of broken pieces.

Countermeasures: Please use safety item, such as safety glasses and protective gloves

Early exchanging tools is preferable.

Precariousness: Dispersion of heated or prolonged chips may cause injury or burn.

Countermeasures: Please use safety item, such as safety glasses and protective gloves

For chips removal, please stop the machine beforehand and use safety items, such as safety glasses and protectives gloves.

Precariousness: Tools and materials reach high temperatures during cutting operation. Direct touch to the tools and materials shortly after cutting may cause burn.

Countermeasures:Please use safety item, such as safety glasses and protective gloves

Precariousness: Sparks, generation of heat or chips in high temperature during operation may cause file.

Countermeasures: Please do not operate around Hazardous zone, in which there is some possibility of fire or explosion.

In case of using oil-coolant, please make sure there is sufficient fire-protection equipment.

Precariousness: Lack of dynamic balance during high-speed revolutions leads to vibrations which can make the tool break.

Countermeasures: Please use safety item, such as safety glasses and protective gloves

Please conduct test-operation before cutting, and confirm that there is no vibration or unusual sound.

Precariousness: Direct touch to the burs which were generated on the rough surface of the workpiece may cause injury.

Countermeasures: Do not touch the workpiece with bare hand.

2.Indexable Cutting Tools

Precariousness: If the insert or other tool parts are not installed properly, they can fall down or break which may cause injuries.

Countermeasures: Please clean up insert pockets or clamping parts before setting insert.

Please set up inserts with supplied wrench only, and confirm that the inserts or parts are clamped completely. Never use inserts or parts other than those prescribed.

Precariousness: If inserts are clamped too tightly by supplementary tools like pipe etc. inserts or body may break.

Countermeasures: Do not use aids such as pipes. Please set up using supplied wrench only.

Precariousness: When tools are used in high-speed revolution, inserts or parts may burst out of the body due to centrifugal force. When handling, please pay special handling to safety.

Countermeasures: Please use in the range of our recommended cutting condition. Accuracy and balance of machine spindle should be checked and adjusted regularly to prevent wear of the bearing due to eccentric rotation.

3.Milling Cutters and other Cutting Tools

Precariousness: Since milling cutter have sharp edged, direct contact with bare hands may cause injury

Countermeasures: Please use safety item, such as safety glasses and protective gloves

Precariousness: If a cutter lack balance, the tool can start to vibrate. The dispersion of broken piece can cause injuries.

Countermeasures: Please use in the range of our recommended cutting condition.

Accuracy and balance of machine spindle should be checked and adjusted regularly to prevent wear of the bearing due to eccentric rotation.

4.Drilling

Precariousness: When drilling a through-bore, it is possible that a disc is created during the drilling procedure that can fly out of the workpiece at a high speed.

This is very dangerous since the disc has sharp edges.

Countermeasures: Please use safety items, such as safety glasses and protective gloves. Also attach a cover on a chuck part.

5.Brazed Tools

Precariousness: Dispersion of falling down of broken inserts may cause injury.

Countermeasures:Please Check that the cutting inserts are brazed firmly before use.

Please do not use brazed tools in the condition that requires high cutting temperature.

6.Others

Precariousness: If Brazing is carried out many times, the strength of carbide insert is deteriorated and can break easily during cutting

Countermeasures: Please do not use tools that have brazed several times. The quality of the tool deteriorates.

Precariousness: The tools can only be used for the appropriate application. It may damage tools and machines.

Countermeasures: Please follow our recommended usage for the tools.

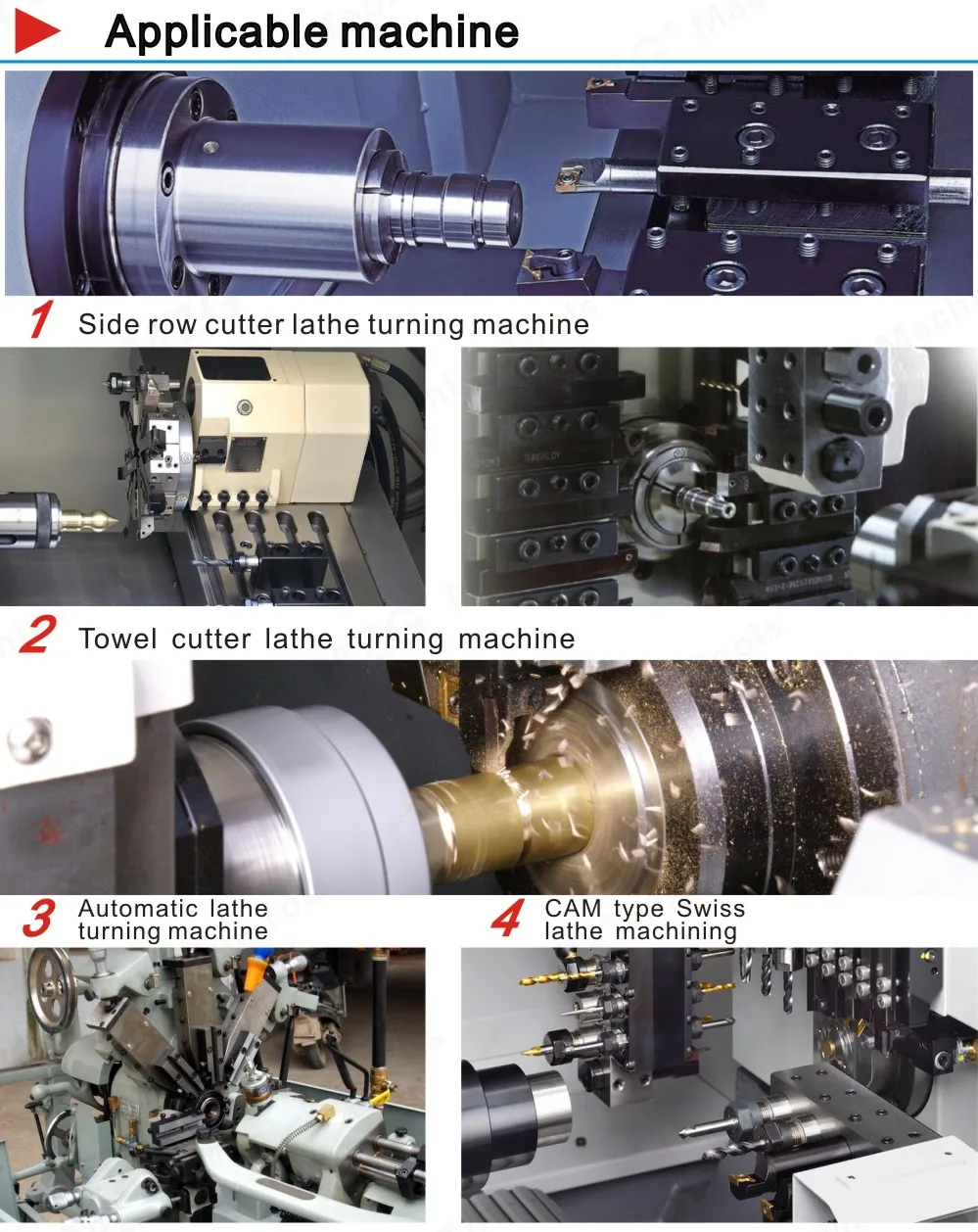

6.MZG Turning Tool Application

Application Machine:

Side row cutter lathe turning machine

Towel cutter lathe turning machine

Automatic lathe turning machine

CAM type Swiss lathe machining

Turning Applicable machine

Processing mode and Finished product samples

Internal Turning

External Turning

Grooving ,Cutting, Face cutting

Thread Turning

Shallow Groove Machining

Small Hole Machining

Turning Processing Mode

7.Buying Tips

1.Picture :

The picture showing at our store are taken by MZG on the true products. Because of different light condition or camera problem, if the color of packing is a little different,that would be normal.,

2.Payment :

When make payment using ESCROW your money is deposited securely we accept ESCROW. Credit Cards, T/T, West Union in your account.

Money is only released to us after you confirm delivery.

If you have any problem of payment, please contact us asap.

3.Refund :

4.Delivery :

EMS : 5-15 days to worldwide Fast, cost normal

TNT : 5-15 days to worldwide Fast, cost high

CHINA POST : 12-26 days to worldwide slow, cost low

We are not responsible for any import tax or custom duty.If the tax or duty is high in your country, please inform us to declare low value in 24 hours after the payment or we will declare the actual value, courier cost is not included. For Russia Federation and Brazil, we suggest EMS & CPAM (China Post Air Mail) full name will be needed For Brazil, we suggest EMS & CPAM, CPE No. will be needed.

5.Feedback :

Your satisfaction and positive feedback is very important to us. Please leave positive feedback and 5 stars if you are satisfied with our items and service.

If you have any problems with our items or services, please feel free to contact us first before you leave negative feedback.

We will solve the problems quickly and promise you 100% good products and services.

Your encouragement and support is our continuously forward momentum.

8.MZG Machine Tools Brand Introduction

Improve THE production Efficiency by 30%

Specialize In Turning, Milling, Threading and Boring machining field

MZG brand mechanical tool selection instructions

NOTE 1 .Please pay attention to unit quantity and unit price when choosing goods :

1.1 : We use main picture and descriptions to express our products as much as possible.If you have any questions about our products, please contact us to confirm the relevant information;

1.2 : About unit,1 piece is one pcs,not a box(For example,Many inserts are composed of 10 pieces to form a box,5 pieces to form a box or 2 pieces to form a box and so on);

1.3 : All of our products support retail. Many of our online products are sold in a box or a pack. If dear customers need to pay for a single item should contact us to change the unit price;

1.4 : About the clamped-type tool doesn't include the tool handle and tool head ,We are sold is separate product, not a combination of products, please note that the purchase of the specifications you choose is the tool part you need;

1.5 : About product packaging, MZG brand product packaging and labeling, according to the brand system adjustment and product batch there will be a certain degree of difference.

NOTE 2 .About product discounts and targeted customer discounts :

2.1 : The store has multiple offers, please take the coupon before placing the order;

2.2 : For the first purchase of customers, due to the customer's own lack of understanding of the shop product have disputes, the Company will issue directional coupon compensation. (Please cancel the dispute and give five-star rating)

NOTE 3 .Due to we store had set in most countries and regions is free shipping, about free shipping, we illustrate as follows :

3.1 : We usually choose is AliExpress Standard Shipping for free shipping goods;

3.2 : Due to the uncertainty of international logistics, please do not choose Promised Time, if you need Promised Time,please according to your country choose DHL, UPS and other international courier, related shipping costs can contact us to modify;

3.3 : For the weight of more than 100kg or volume of more than 0.5m⊃3;, we will according to the actual situation, the shipping costs for varying degrees of relief, and using the appropriate logistics or sea shipping of service.

NOTE 4 .Wholesale and OEM service instructions :

4.1 : Our store has set up the purchase discount in bulk price, can choose by themselves ;

4.2 : If you need Bulk purchase, please contact customer service alone.I can give you preferential shipping prices, I will use the sea transport for send goods ;

4.3 : We provide customers with customized services, such as customers haven't need brand Logo products,please contact us immediately after placing an order and inform you of delivery requirements,we can provide OEM services for large quantities of purchase orders.

MZG Machine Tools MZG Turning Tools MZG Boring Tools MZG Milling Tools MZG Threading Tools

Copyright@http://www.mzginj.com/Bengali all rights reserved 粤ICP备10018249号-6

Copyright@http://www.mzginj.com/Bengali all rights reserved 粤ICP备10018249号-6